The Nissan Cabstar is a light commercial vehicle that has gained a reputation for being reliable and durable.

However, like any vehicle, it can experience issues with its gearbox that can affect its performance and longevity.

These Nissan Cabstar Gearbox Problems can range from difficulty in selecting gears to gearbox noise, slipping, and jumping out of gear.

In this article, we will explore the common gearbox problems that Nissan Cabstar owners may encounter, along with their symptoms and possible causes.

Table of contents

What Is the Main Problem in The Gearbox?

Gearbox issues can manifest in various ways in Nissan Cabstar vehicles, which can impact the overall performance of the vehicle.

Difficulty selecting gears is a common issue that can indicate problems with the gear linkage or worn gearbox synchros. Delays in shifting are usually the result of poor maintenance or high mileage in automatic transmissions.

Jumping out of gear is usually a manual transmission fault caused by worn gearbox synchromesh cones or damaged gearbox mounting.

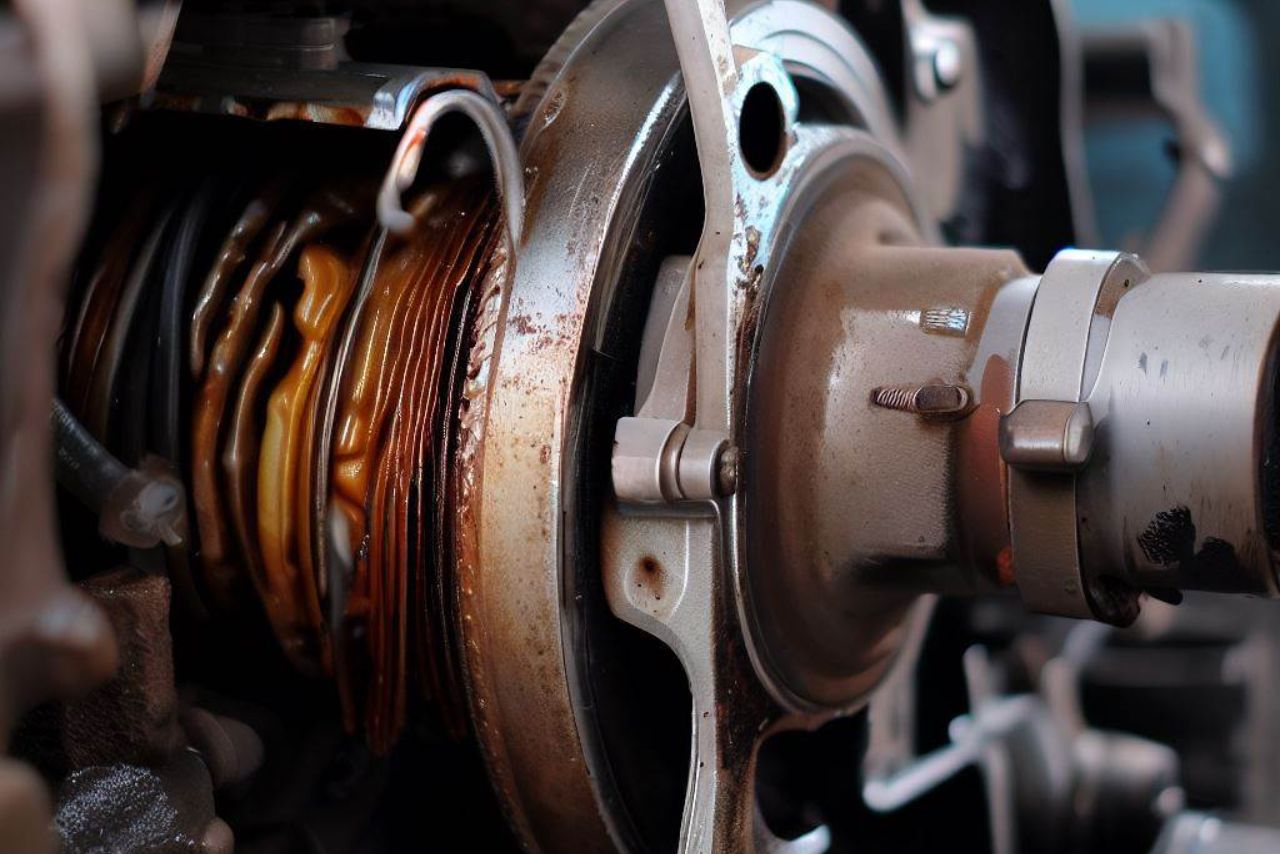

Gearbox noise can be caused by worn gearbox mounts, worn synchros, or damage to the gear teeth or gear hub bearings. Old and burnt transmission fluid in automatic transmissions can cause issues with delayed shifting.

To address these gearbox issues, regular maintenance and care are necessary. Proper gearbox maintenance can include oil changes, which can prevent wear and damage to the gearbox internals.

It is also essential to have a local mechanic check the gearbox immediately if issues arise.

If the Nissan Cabstar is jumping out of gear, despite simple fixes such as adjusting the gear linkage, the vehicle should still be checked over.

If there is a whistling or whining noise, it is advised to get the gearbox checked as soon as possible. If metal filings are found when changing the oil, it is necessary to get a more detailed gearbox inspection.

Common Nissan Cabstar Gearbox Problems:

Difficulties with gear shifting and delays in changing gears are common issues in Nissan Cabstar vehicles.

In manual transmissions, these problems are often caused by worn synchromesh cones or poor maintenance.

Gear linkage adjustment can sometimes fix the issue, but a more thorough inspection by a skilled technician may be necessary.

| Problem | Symptoms | Causes | Solutions |

|---|---|---|---|

| Gearbox noise | Squealing, whining, humming, or banging noises | Worn gears, bearings, or seals, low transmission fluid level, or damaged transmission mounts | Repair or replace the damaged components, add transmission fluid, or replace the transmission mounts |

| Gear slipping | Difficulty shifting gears, gears that pop out of gear, or gears that grind when shifting | Worn or damaged gears, clutch problems, or low transmission fluid level | Repair or replace the damaged components, adjust the clutch, or add transmission fluid |

| Gearbox delay | Delays in shifting gears, especially when accelerating or decelerating | Low transmission fluid level, worn or damaged gears, or transmission problems | Add transmission fluid, repair or replace the damaged components, or rebuild the transmission |

| Gearbox overheating | Transmission fluid that is too hot, transmission fluid leaks, or transmission problems | Check the transmission fluid level and condition, repair or replace any leaks, or rebuild the transmission | |

| Gearbox failure | The transmission will not shift gears, or the transmission will lock up | Severely worn or damaged gears, clutch problems, or transmission problems | Rebuild or replace the transmission |

| Gearbox vibration | Vibrations when shifting gears, or vibrations when driving at certain speeds | Worn or damaged gears, transmission mounts, or driveshafts | Repair or replace the damaged components, or adjust the transmission mounts |

1. Gearbox whining or grinding noise:

A noticeable whining or grinding noise emanating from the vehicle may be indicative of a more serious issue with the transmission system, requiring immediate attention from a skilled technician.

Gearbox noise can be caused by a range of issues, including worn gearbox mounts, damaged gear teeth or hub bearings, or worn synchros.

Here are some troubleshooting steps to take when dealing with gearbox noise:

-

Diagnosing causes: The first step in dealing with gearbox noise is to identify the cause. This can be done by listening to the noise carefully and noting when it occurs. Is it constant, or does it only occur when shifting gears? Does it change in pitch or volume as the vehicle speeds up or slows down? These details can help a skilled technician narrow down the cause of the noise.

-

Proper maintenance techniques: Regular maintenance can prevent many gearbox issues from occurring in the first place. This includes changing the gearbox oil at regular intervals, inspecting the gearbox for wear and damage, and replacing worn or damaged parts as needed.

-

Finding a mechanic: When dealing with gearbox noise, it’s important to find a skilled technician who has experience working on the Nissan Cabstar or other commercial vehicles. Look for a mechanic who is familiar with the make and model of your vehicle and who has a reputation for quality work.

-

Troubleshooting steps: If you’re experiencing gearbox noise, there are a few troubleshooting steps you can take before taking your vehicle to a mechanic. These include checking the gearbox oil level and condition, inspecting the gearbox mounts for wear or damage, and checking for loose or damaged parts in the transmission system. However, it’s important to remember that gearbox issues can be complex and difficult to diagnose, so it’s always best to seek the advice of a skilled technician.

2. Delayed or harsh gear changes:

Delayed or harsh gear changes can be a frustrating issue for drivers of Nissan Cabstar vehicles, affecting the overall performance and drivability of the vehicle.

These symptoms can be caused by a variety of issues and require proper diagnosis to identify the root cause. Poor transmission maintenance, worn gearbox synchros, and damaged transmission mounts are common causes of delayed or harsh gear changes.

To address this issue, it is recommended to have a professional inspection to diagnose the exact problem.

Regular gearbox oil changes can also prevent wear and damage to the gearbox internals, which can lead to delayed or harsh gear changes.

If the issue is with the clutch, a clutch replacement job may be necessary to restore proper function.

Proper gearbox repair and maintenance can help prolong the lifespan of the vehicle and ensure smooth gear changes.

3. Gearbox slipping:

One potential issue that can arise in the operation of a commercial vehicle’s transmission system is the occurrence of gearbox slipping, which can result in reduced power delivery to the wheels and potential damage to the gearbox internals.

Gearbox slipping occurs when the transmission slips out of gear while driving, causing the engine to rev but the vehicle to lose power.

This can happen due to worn clutch plates, damaged gears or synchros, or low transmission fluid levels.

To diagnose gearbox slipping, a mechanic may perform a visual inspection of the transmission system to check for any obvious signs of damage or wear.

They may also use diagnostic tools to read any error codes that may be present in the vehicle’s onboard computer system.

Fixing techniques for gearbox slipping will depend on the specific cause of the issue, but may include clutch replacement, gearbox repair, or even gearbox replacement.

Repair costs for gearbox slipping can vary widely depending on the extent of the damage and the specific repair techniques needed, but can be quite expensive.

To prevent gearbox slipping, regular gearbox maintenance is essential, including regular oil changes and inspections to catch any potential issues before they become major problems.

4. Gearbox failure:

Gearbox failure can lead to significant damage and costly repairs, making it crucial to address any issues promptly.

If left unchecked, gearbox failure can result in catastrophic damage to the vehicle’s drivetrain, resulting in costly repairs and significant downtime for commercial vehicles like the Nissan Cabstar.

To avoid such issues, regular gearbox maintenance is essential, including oil changes and inspections.

If there are any signs of gearbox issues, such as difficulty selecting gears, delays in shifting, or jumping out of gear, it is crucial to have the gearbox inspected and diagnosed by a professional mechanic.

Regular gearbox inspections can help identify potential issues before they become costly and time-consuming repairs.

If gearbox failure is inevitable, it may be necessary to replace the gearbox entirely, which can be a costly and labour-intensive process.

However, with proper gearbox maintenance and diagnostics, most issues can be resolved without the need for a full gearbox replacement.

5. Jumping out of gear:

The sudden disengagement of a vehicle’s gear while driving can lead to dangerous situations and cause significant damage to the drivetrain. This is a common issue with manual transmissions, and it is known as ‘jumping out of gear.’

The problem can be caused by various factors, including worn synchromesh cones, damaged gearbox mounting, or gear linkage adjustment issues.

When the driver experiences the gear disengagement, they should immediately stop the vehicle and seek professional help to diagnose the issue.

To prevent this problem from occurring, proper maintenance is crucial.

Regular gearbox oil changes can prevent wear and damage to the gearbox internals, and it is essential to have a suitable gearbox technician repair the gearbox if it turns out to be a synchromesh issue.

Additionally, if the gearbox noise is caused by worn gearbox mounts, the mechanic should fix the issue to prevent the gears from slipping out of position.

Therefore, Nissan Cabstar owners should follow a rigorous maintenance schedule to avoid gearbox issues and ensure their safety on the road.

6. Old gearbox oil & Clutch issues:

Moving on from the issue of jumping out of gear, we now turn our attention to two other related gearbox problems that can arise in Nissan Cabstar vehicles. These include old gearbox oil and clutch issues.

Proper lubrication is crucial in preventing wear and tear of gearboxes. One way to ensure proper lubrication is by regularly replacing the oil in the gearbox.

Old and burnt transmission fluid in automatic transmissions can cause issues with delayed shifting, while manual transmissions need oil too.

If the oil is old, it may not lubricate the gears as well, causing wear and damage.

Regular servicing and oil replacement can go a long way in preventing such issues. Clutch issues may also be mistaken for gearbox issues, such as a hard clutch pedal or slipping clutch.

Proper clutch maintenance, including regular servicing, can help prevent such issues and ensure smooth shifting.

A summary of the key points on replacing oil and clutch maintenance is presented in the table below.

| Key Points |

|---|

| Regularly replace gearbox oil to ensure proper lubrication |

| Old and burnt transmission fluid can cause delayed shifting |

| Manual transmissions need oil too |

| Proper clutch maintenance can prevent issues such as slipping clutch |

| Regular servicing can prevent wear and tear |

Symptoms of Nissan Cabstar Gearbox Problems:

Symptoms of wear and tear in a commercial vehicle’s transmission system can include difficulty shifting gears, delayed shifting, and unusual noises.

It is important for Nissan Cabstar owners to be aware of these signs in order to prevent further damage to the gearbox.

Troubleshooting tips, such as adjusting the gear linkage or checking the transmission fluid level, can help diagnose the problem and determine whether it is a simple fix or a more complex issue.

Common misconceptions surrounding Nissan Cabstar gearbox problems include mistaking clutch issues for gearbox problems, and assuming that gearbox noise is normal.

Regular maintenance, such as changing the gearbox oil and having a professional mechanic inspect the gearbox, can prevent these issues from occurring.

If a repair is necessary, it is important to weigh the cost of repair versus replacement, and to choose a suitable gearbox technician to fix the issue.

Overall, taking care of the Nissan Cabstar’s gearbox through proper maintenance can help ensure its longevity and prevent costly repairs in the future.

Prevention and Maintenance

Proactive maintenance and care are crucial to ensure the longevity of a commercial vehicle like the Nissan Cabstar.

Regular checks and servicing can prevent costly gearbox repairs and unexpected downtime.

Proper maintenance includes regular gearbox oil changes, which can prevent wear and damage to the gearbox internals.

The gearbox oil should be changed at least every 50,000 miles, or more frequently if the vehicle is used in heavy-duty applications.

In addition to oil changes, commercial vehicle care should include a thorough inspection of the gearbox by a professional technician if there are any issues or unusual noises.

Metal filings found in the oil during a routine oil change could indicate more serious problems that require a more detailed gearbox inspection.

It is also important to have worn gearbox mounts or synchromesh cones repaired promptly to prevent further damage to the gearbox.

A rigorous maintenance schedule, including regular inspections, oil changes, and prompt repairs, can ensure the gearbox’s longevity and prevent unexpected downtime.

Frequently Asked Questions:

How does the Nissan Cabstar compare to other commercial vehicles in terms of dependability?

In terms of reliability comparison, fuel efficiency, maintenance costs, cargo capacity, and safety features, the Nissan Cabstar generally fares well among commercial vehicles. However, specific models and usage can vary, and thorough research and consideration is recommended before purchasing.

What are some potential causes of a squeaking noise when shifting gears in a Nissan Cabstar?

The potential causes of a squeaking noise when shifting gears in a vehicle may include worn-out components such as the clutch, gearbox mounts, or synchromesh cones. Proper diagnosis and maintenance can prevent and provide solutions for such issues.

How can a damaged gearbox mounting be identified and repaired in a Nissan Cabstar?

Identifying a damaged gearbox mounting in a vehicle involves inspecting the mounting points and brackets for signs of wear, cracks, or corrosion. Repairing the mounting typically involves removing the gearbox, replacing the damaged component, and reattaching the gearbox, which can be a labor-intensive process in the Nissan Cabstar.

Are there any potential issues with automatic transmissions in Nissan Cabstar vehicles?

Potential issues with automatic transmissions in Nissan Cabstar vehicles may include delayed shifting, caused by old or burnt transmission fluid, and worn out clutches, bands, and solenoids. Regular transmission maintenance, including fluid changes and rebuilds, can prevent these problems and avoid the need for costly gearbox replacement or repair.

What are some common symptoms of clutch issues in Nissan Cabstar vehicles, and how can they be addressed?

Common symptoms of clutch issues in commercial vehicles like the Nissan Cabstar include a hard clutch pedal or slipping clutch. Common solutions include regular maintenance, DIY fixes such as adjusting the clutch cable, or seeking professional repair or replacement options. Preventative maintenance can also help avoid clutch issues.

Conclusion and final thoughts 💭

Nissan Cabstar gearbox problems can be a frustrating issue for owners, affecting the performance and longevity of their vehicles.

Common issues include difficulty selecting gears, delays in shifting, jumping out of gear, and gearbox noise.

These issues can be caused by various factors, such as old gearbox oil, clutch issues, or general wear and tear.

To prevent and maintain the gearbox, regular oil changes and seeking the advice of a local mechanic are essential. It is important to address any symptoms immediately to avoid further damage and costs.

Overall, by taking proactive steps and addressing any issues promptly, Nissan Cabstar owners can ensure their vehicles perform optimally and last for years to come.

Latest Posts:

- Can WD-40 Remove Scratches on Cars? (Hint: Yes, but…)

- Can You Use a Drill to Polish Your Car? (We Tried it Out!)

- Should You Cover Car Scratches With Stickers? (REVEALED!)

- Buick Service Stabilitrak: (Causes & 100% Guaranteed Fix!)

- Common Holden Trax Problems (Causes & 100% Proven Fixes!)

- Jeep Commander Transmission Over Temp: (Guaranteed Fix!)

Leave a Reply